![]()

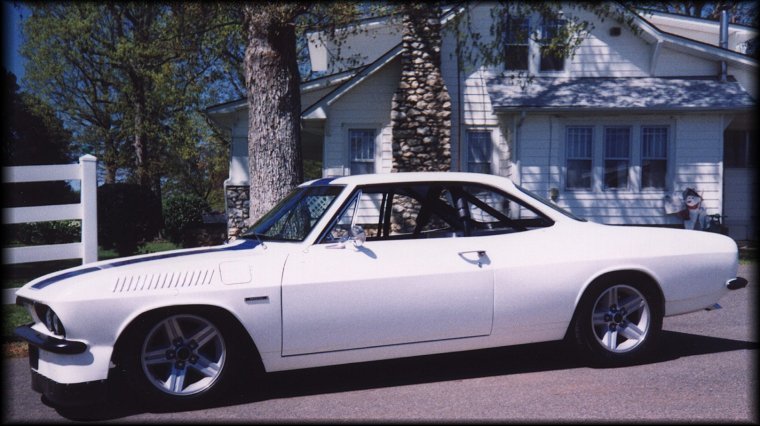

John "Buck" Burkett's Monzilla - a Buick-powered 500

|

The panels on either side of the air intake provide access to the ignition and battery components on the driver's side, and on the passenger side as seen at right, to the oil reservoir, Oberg filter, temperature gauges and power plug-in socket for the oil heater. Yes, the engine oil can be pre-heated before start up. Borrowing a page from NASCAR race engine design, John uses a dry sump oiling system. Also popular in professional NHRA drag racing, dry sump systems limit parasitic drag inside the engine by using a large remote oil reservoir, an externally mounted, crank driven, multi-stage, oil pump and a specially designed oil pan. They also provide more ground clearance for engines mounted in a low slung chassis, as the oil pan tends to be more shallow, needing only to clear the crankshaft. |

|

|

John explains, "The oil pump is really multiple pumps, called stages, arranged side by side in a single assembly driven by a common shaft. The designs vary but these pumps are typically 4 or 5 stage units. One of the stages pulls oil from the reservoir, then pumps it through a cooler, then to a racing quality spin-on filter before delivering it under pressure to the engine. The remaining stages vacuum oil from the pan and return it to the reservoir through an Oberg filter. The Oberg is a screen filter designed to be quickly and easily opened to allow inspection of its screen. All of the oil returning from the engine passes through the screen leaving behind any metal particles and providing easy diagnosis of engine condition. The pans themselves are a work of art/science/black magic. Designs vary by race track, but the principle is the same. The inside of the pan is designed to capture the oil flowing from the bearings and channel it to the scavenge pickups on both sides of the pan while segregating it from the rotating crank and rods. Any oil flying around in the crankcase robs horsepower, maybe not much, but stack a bunch of small gains together and they become advantages. The winner's circle awaits the team with the most advantages. That is why race engines are so expensive, every component has been designed and assembled with maximum performance/durability in mind. That extra 5 HP could mean a lot at the end of a 500 mile race. The whole car gets the same attention to detail with the focus on gaining every ounce of performance." John points out that NASCAR engines are pampered like thoroughbred horses, adding, "Before an engine is started, the oil in the reservoir is warmed with powerful heating elements in or around the 18 quart reservoir. When the oil reaches 300 degrees the oil pump drive belt is slipped off and the pump is spun by drill to build pressure and circulate the hot oil to the engine. When the oil is the right temperature, the belt is replaced and the engine started. The object is to make sure the engine is well lubricated each time it is started. The proper temperature is very important. Generators near the cars during qualifying and prior to the race are connected to heaters for the engine oil, and rear end. A NASCAR racer does not want to qualify with the oil cold and thick as it takes more HP to pump it in that state, and it causes drag anywhere it touches. Normally only the engine oil is heated prior to the race to insure that proper temps are reached during the pace laps." |

|

John's mighty Buick V-6 ran at Daytona when it was in his team's Busch car. It was also in the team car when they won a race at Indiannapolis Raceway Park. With a 390 CFM Holley carb and without a restrictor plate, the engine made 480 HP on the Dyno! Since being installed in Monzilla, the carburetor has been changed in favor of a 780 Holley, which John says adds another 100 HP! Now wait a minute, I think that adds up to 580 HP! All that power required some judicious handiwork at the delivery end, specifically the trans-axle and suspension components. |

|

|

The trans-axle is '66 Corvair, using a 4-spider, limited-slip differential carrier. A cross member was added to the body between the upper spring pockets, and the differential case was drilled and tapped to allow the installation of struts between the differential and cross member. The half-shafts' U-Joints were replaced with the biggest ones John could buy, and the rubber bushings in the struts and trailing arms were replaced with mono balls. |

|

|

The modifications help keep the rear suspension components positioned correctly when subjected to lateral G forces. When I asked John whether he was confident the running gear could handle the power, he said, "Happily the whole assembly seems up to the task. I don't baby it, nor do I buzz the throttle and side step the clutch." |

|

Above, Monzilla is seen at rest with NASCAR legend Richard Petty's boyhood home in the background. Future plans include refining the shift linkage and "definitely" adding disk brakes and maybe some road racing, if the car will pass tech inspection. Kinda gives ya a whole new respect for 6 cylinders, doesn't it? Photos by John Burkett |

Select from the navigation bar!