![]()

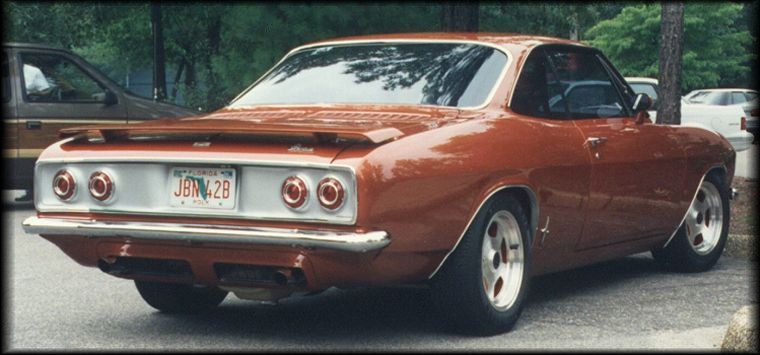

Jeff Brekke's Buick-powered '65

|

Jeff's excellent craftsmanship is also evident in the engine bay. The iron-block, .030 over 231 cubic inch displacement, reverse-rotation Buick V-6 fits perfectly under the stock hood, with fresh air for the Holley carburetor supplied through the standard Corvair inlets and plenum behind the rear window. The Holley is a 390 cfm model with #52 jets. The intake manifold is an aluminum Edelbrock dual plane. Ignition is provided by an MSD billet V-6 Buick distributor with distributor gears cut to allow for correct oil pump rotation, and an MSD 6A box (upper right in photo). At the lower left is an Airtique air-conditioning compressor, and at the extreme left, an aluminum panel with quick release fasteners gives access to the battery in its stock location. A coolant recovery tank is seen in the upper left hand corner of the picture, is the highest point in the cooling system and is used for filling and to purge air. At the right in the photo, a compact spare tire replaces the stock full size spare. |

|

The engine uses forged pistons and the stock compression ratio, and the connecting rods were rotated for proper power stroke geometry. The new firing order is 1-2-3-4-5-6. The engine's cam rotation is in reverse and driven using a Milodon gear drive with an idler gear. The cam is a Howard's billet roller cam (.488 intake and exhaust w/112 degree centerline) made for reverse valve timing. The valves are motivated by Isky full skirt roller lifters (solid; .026 lash) and the valve train uses a T&D Machine aluminum roller rocker shaft system. All rotating assemblies were balanced. A water pump pulley was fabricated with the belt drive on the back side, similar to an idler pulley. The crank shaft oil seal surface was filled and polished to prevent oil from being directed out past the seal, and the starter internals were reversed. The front-mounted radiator is a Modine unit intended for Chevy Caprice and Cadillac replacements. It is mounted in a vertical configuration between the headlights. Coolant lines are routed to the rear of the car inside the floor pan tunnel. Jeff made the engine-to-transaxle adapter out of 6061-T6 aluminum .25 inch sheet. He cut out the two bolt patterns and rolled the center. The center was welded to the engine plate first. He left about .5 inches in extra length to be later removed in a lathe for truing. The transaxle pattern was then welded in while the engine and transaxle were mocked up together. After all the welding, the whole thing was put back in the lathe for any necessary truing or facing on both ends. The transaxle is a '66-69 Corvair 4-speed Saginaw unit with a 3.27:1 final drive ratio. A new hydraulic clutch arrangement makes use of a slave cylinder intended for older Ford trucks. |

|

The stance of the Corsa is excellent! Jeff lowered the front of the car by cutting one coil out of front springs. Springs are stock at the back of the car with the Corvair independent rear suspension retained and set to slight negative camber. A set of Weiand headers feed the dual exhaust pipes which exit through the blacked out inserts of the three piece stock Corsa air exhaust grill. The rear was further modified by discarding the back-up lights in favor of a second set of brake lights. This was accomplished by changing out the lenses and rewiring the inner units. While the Corvair purist might not be able to live without a genuine Corvair engine under the deck lid, many would find it difficult to find fault with Brekke's setup. The Buick V-6 makes approximately 205 hp and 269 lb-ft of torque @ 4000 rpm and 274 hp and 261 lb-ft of torque @ 5500 rpm. Jeff's had the car to 105 mph (under controlled conditions, of course ;>) and says it feels great at that speed, and under normal highway conditions, seems to have plenty of safe passing power. I believe it. Well done, Jeff! Contact Jeff by e-mail: Brek86@msn.com Photos by Rick Norris |

Select from the navigation bar!