![]()

Dave Binnie's Blow-through Turbo

|

Site visitors often ask for more technical detail, and on the following pages, large, close-up pictures provide an excellent view of the various components and modifications necessary to achieve good results with the blow-through setup. Those who are more interested in interior and exterior photos won't be disappointed, as more of those pictures follow the tech photos. Before we begin, it's interesting to note that according to Dave, the blow-through setup was introduced by Bill Thomas Race Cars in 1963, and there were kits sold at the time. The popular impression that blow-through turbochargers don't work is perpetuated in part by a less than positive reference in the book, How to Hot Rod Corvair Engines by Bill Fisher. Bill reported that the driver of a blow-through turbo car "had to resort to speed shifting to prevent blower stall and carburetor confusion." While Dave recognizes Bill's book as a great book, and doesn't disagree with his assessment of that particular setup, he's just not one of those guys who will easily dismiss what he believes to be a great idea, and he set out to solve the problems associated with the early design. "A factory Bosch turbo compressor by-pass valve is essential to proper system performance," he says. That, along with other design modifications and tuning, results in a "glass smooth idle" and "instantaneous" boost in any gear, in contrast to the stock turbocharged Corvairs. He explains that because the stock turbocharger setup used long intake runners between the carburetor and cylinder heads, it resulted in less than optimum fuel atomization and a weaker vacuum signal at idle. Although the stock 150 or 180 hp turbocharged engines are good performers capable of making up to 10 pounds of boost under a load in high gear, they typically make much less boost in the lower gears than the blow-through arrangement. So, that being said, let's have a look at Dave's blow-through setup from top to bottom; from the tip of the air cleaner snorkel to the engine's internals. |

|

Air cleaner: In the picture at right, notice the air cleaner is repositioned from the stock orientation. This way it ingests air from the cool air plenum instead of the hot environment of the engine compartment. Dave points out that the area of the inlet of the stock air cleaner's rounded rectangular snout matches perfectly the round 3-inch outlet pipe he TIG welded on the outlet side to mate with the turbo. This improves flow from the stock setup, as does the oil-impregnated K&N filter element he uses in place of the stock element. |

|

|

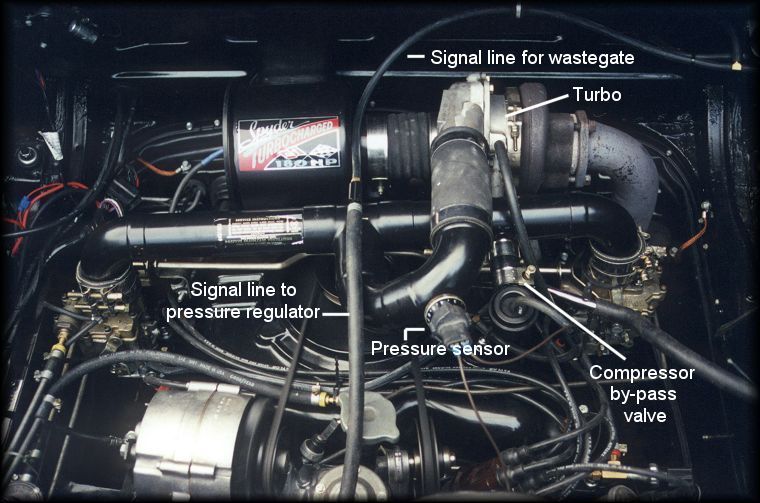

Turbocharger: The turbocharger housing is stock Corvair. The impeller was replaced with a more aggressive E-Flow unit. Then, with the help of his friend Rodney Mosher, a professional turbine engineer, Dave determined the optimum clearances to use to shim the impeller for best boost. Boost is adjustable, and is currently set to 10 pounds. The turbo boost threshold, the point at which boost starts to occur, is 1700 rpm. Useable boost is encountered at 2700 rpm. More details on the function of the turbocharger and associated systems follow, later in the article. You'll note in the picture below, the "Spyder Turbocharged 180 hp" decal on the air cleaner housing. This is a Clark's Corvair Parts reproduction of the decal installed on some early 1965 Corsa models, significant because the Spyder series was replaced by the Corsa in '65, and the factory actually mislabeled some engines during early production. GM later switched to a sticker reading, "Corsa." The horsepower rating on the sticker doesn't match the output of Dave's engine, but it's a historically significant conversation piece. |

|

Intake plenum and associated hardware: Dave fabricated a custom intake plenum out of 2-inch copper tubing, and joined it to the turbocharger with industrial grade radiator hose. Mounted on the intake elbow is a pressure sensitive switch to activate water injection. The insertion point of the water injection system is located immediately in front of the turbocharger. The turbo compressor by-pass valve is a Bosch unit like the one used on Saab turbo models. |

Click the road sign for more.

Select from the navigation bar!