![]()

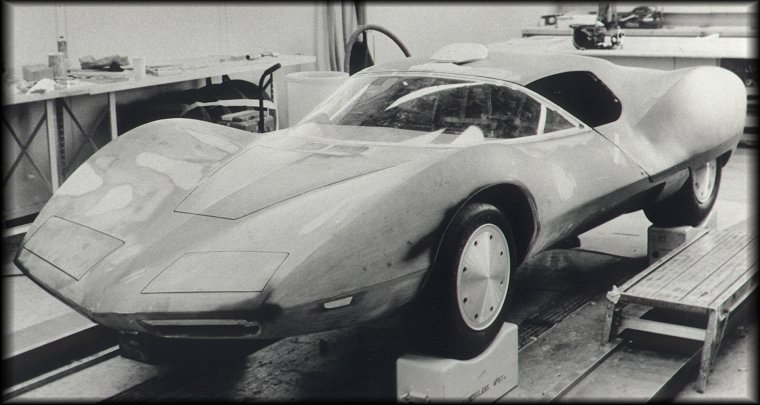

Astro-I Design Study

|

According to SCCA racer, Seth Emerson, the engine's carburetors were not standard Weber. He quotes good sources who claim they were GM castings, completed with Weber parts. The modification of the carbs was necessary because of bore-to-bore differences. The throats on the Astro I carbs were much wider apart than the Weber 40IDA 3-barrels. The Corvair cylinders (hence the intake valves) were further apart. Seth has run the 40IDA 3-barrel Webers on many engines, and indicates if you center the middle cylinder, both outer cylinders have to have the manifold turn out to meet the head. He says that's why GM cast their own bodies. An experienced Weber man can tell by the distance between the fuel inlets on the sides. |

|

Here we see the Astro-I under construction. The underbody featured unit construction, with hefty, boxed side sills and integrated belly pan and bulkheads. A rubber, anti-slosh fuel cell was located in the sill on the passenger side to offset the weight of the driver. Roll protection was provided by the bulkhead behind the seats, which extended above the heads of the car's occupants. Further protection was afforded by a forged aluminum windshield header. The Astro I suspension exhibited advanced anti-dive and anti-squat characteristics, and used double wishbones at both front and rear. Cooling of the all-around disc brakes was aided by ram-air from the integrated scoops in the front turn signals and on the body sides. Further consideration was given to cooling the brakes in the design of the wheels, which provided for optimum disc sizing. Cast of magnesium in two pieces, the outer portion of the wheels could be removed for tire changes, and could be equipped with alternate rims to facilitate a change to wider tires. Nominal widths were 5.5 inches/front and 7.0 inches/rear. The flush design of the wheels contributed to the car's aerodynamic efficiency. |

Click the road sign for more.

Select from the navigation bar!